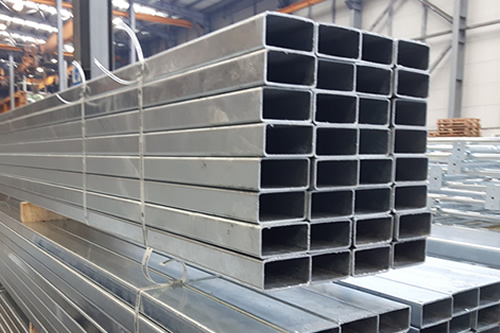

Turkish Manufacturer of ERW Pipes

Turkish manufacturer of steel ERW pipes, Our process that leads the way in steel manufacturing industry quality. We take pleasure in manufacturing premium Electric Resistance Welded (ERW) steel products that meet and beyond industry standards. Our legacy is rich in innovation.

About Us:

We are precision, strength, and durability architects rather than just manufacturers of steel. Founded with the goal of making a contribution to the global steel industry, we are able to provide goods that meet a wide range of industrial needs thanks to our state-of-the-art facilities and cutting-edge technologies.

Reasons to Select Us:

🌐 Unequaled Proficiency: With years of expertise, our group of knowledgeable experts has a thorough grasp of the steel production process, guaranteeing the creation of superior ERW steel products.

🔬 Innovation Fundamentally: We welcome innovation and keep up with market trends by making investments in cutting-edge technologies. Our commitment enables us to provide products that satisfy our customers’ changing needs.

🌍 Worldwide Presence: With our roots firmly planted in Turkey, our impact is felt all over the world. We have established reliable alliances, serve customers globally, and support the expansion and advancement of numerous sectors.

Our Selection of Products:

Discover a wide selection of ERW steel products designed to satisfy the demanding needs of industrial, infrastructure, and building applications. Our solutions, which range from pipes to structural elements, serve as the foundation for many projects.

Assurance of Quality:

There is no compromise on quality at us. Every step of the manufacturing process is subject to stringent quality control procedures, guaranteeing that our steel products not only meet but also exceed industry requirements.

Accountability for the Environment:

We’re dedicated to environmentally responsible and sustainable activities. We are committed to a more sustainable and environmentally friendly future, which is why our production methods meet the strictest environmental requirements.

Get in Touch With Us:

Discover the world of top-notch steel production by working with [Your Company Name]. We can help you with your demands whether you’re starting a construction project or need dependable steel solutions.

To find out how our Turkish Steel ERW products can take your projects to the next level, get in touch with us right now.

Turkish ERW Producer’s Introduction

Electric resistance welding (ERW) is a steel pipe manufacturing process in which a continuous strip of steel is welded together to form a pipe using electric resistance. ERW pipes are a popular choice due to its low cost, strength, and adaptability.

Turkish ERW producers are key players in the worldwide ERW pipe market. Turkey is a major manufacturer of ERW pipes, accounting for roughly 10% of global output. Turkish ERW manufacturers are renowned for their outstanding quality, affordable pricing, and dedication to customer service.

Method of production

The following phases make up the production process for ERW pipes:

- Steel rolling: Rolling the steel strip to the appropriate thickness is the first stage in the production of ERW pipes. A rolling mill that runs continuously is used for this.

- Forming: The steel strip has to be shaped into the required shape in the following stage. A pipe forming machine is used for this.Preparing the steel strip for welding is the next step in the welding process. This entails scrubbing the steel’s surface clean and filling the weld joint with flux

- Weld seam welding: Next, electric resistance welding is used to fuse the steel strip together. The steel strip is subjected to an electric current in order to melt and fuse the metal together.

- Cooling: Next, room temperature is reached by the welded pipe. A cooling system that runs on water or air is used for this.

- Finishing: After the pipe has cooled, any necessary finishing procedures are carried out and a quality inspection is conducted. This could entail coating the pipe, chamfering the ends, or cutting it to length.

Uses

Applications for ERW pipes are many and include:

- Oil and gas: ERW pipes are utilized in offshore platforms and storage tanks, among other oil and gas applications, as well as in oil and gas pipelines.

- Water and sewer: ERW pipes are utilized in irrigation systems, storm drains, and other water and sewer-related applications in addition to pipelines.

- Building and construction: ERW pipes are utilized for railings, fences, and structural supports in these fields.

- Agriculture: Animal fence and irrigation systems are two uses for ERW pipes in agriculture.

Advantages of pipe ERW

ERW pipes provide several advantages over other kinds of pipes, such as:

- Cost-effectiveness: ERW pipes are a cost-effective solution for a range of applications since they are reasonably inexpensive to manufacture.

- Strength: ERW pipes are suitable for a wide range of applications because of their strength and durability.

- Versatility: ERW pipes are a flexible alternative for a range of applications since they can be produced in a number of diameters and forms.

In summary

Turkey’s ERW pipe industry is dominated by Turkish producers. They provide reasonably cost, premium ERW pipes that are suitable for a range of uses.

Galvanized ERW pipe advantages

Compared to other types of pipes, galvanized ERW pipes have several advantages. These advantages include:

Corrosion resistance: The pipe’s lifespan is increased by the zinc coating’s ability to prevent corrosion.

Strength: Because of its strength and longevity, galvanized ERW pipes are a great option for a range of applications.

Versatility: Galvanized ERW pipes are a flexible alternative for a range of applications since they can be produced in a multitude of sizes and forms.