What is steel mesh?

Steel mesh, a woven or interlocking metal fabric, is a remarkably versatile material with a broad range of applications across various industries. Its unique properties, including strength, durability, and adaptability, make it an indispensable component in construction, manufacturing, agriculture, and decorative arts.

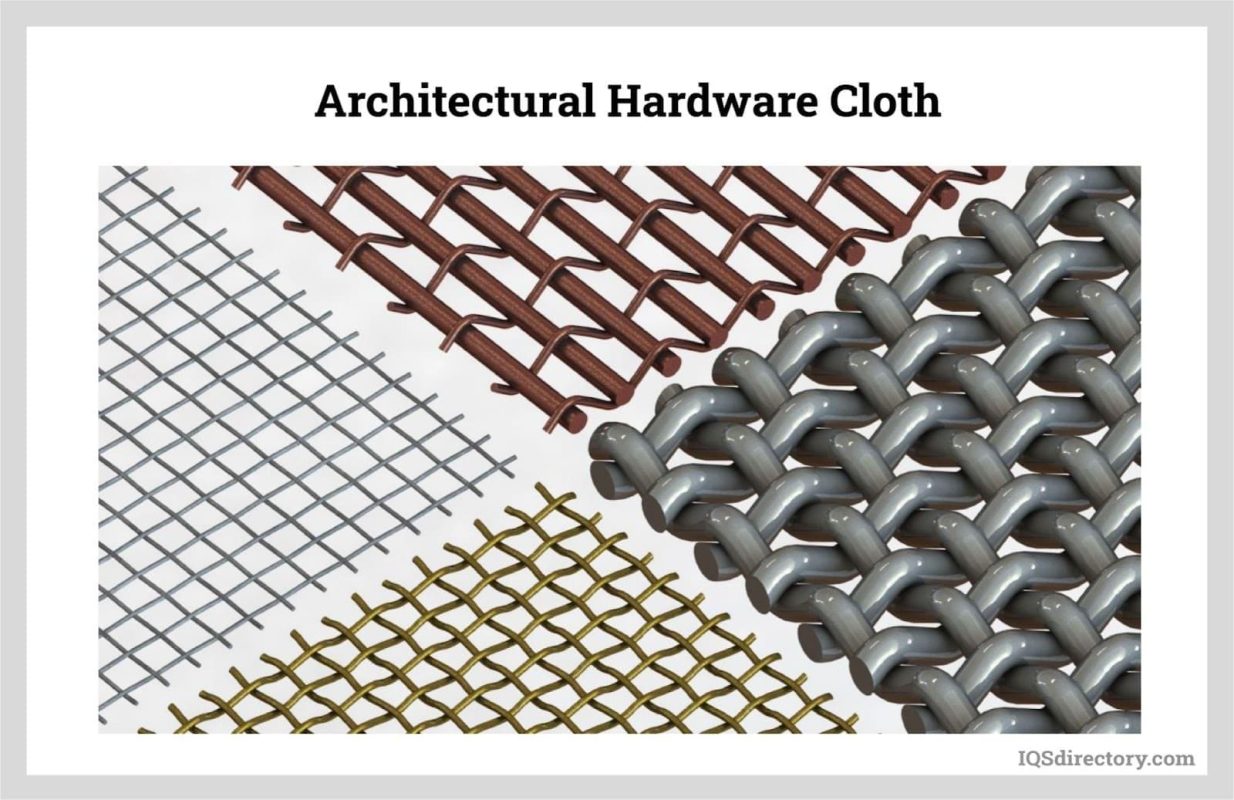

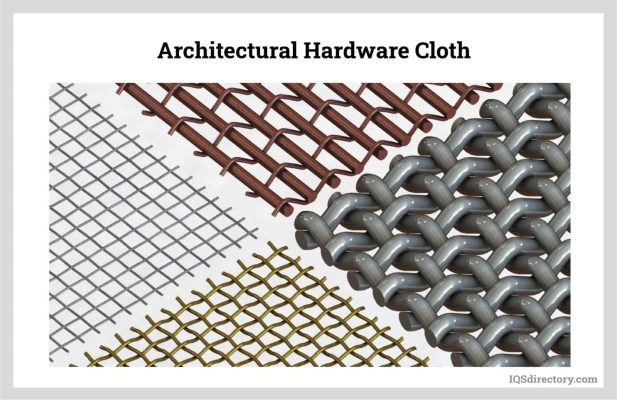

Types of Steel Mesh

- Wire mesh: The most basic form, it’s created by weaving wires together in a simple pattern.

- Expanded metal: Formed by cutting and stretching a sheet of metal, resulting in a diamond-shaped pattern.

- Welded wire mesh: Wires are welded together at their intersections, providing enhanced strength and rigidity.

- Perforated metal: Holes are punched in a sheet of metal, offering a variety of perforation patterns and sizes.

- Woven wire mesh: This type is created by interlacing wires in a specific pattern, resulting in a strong and durable fabric.

- Chain link mesh: Composed of interlocking metal chains, it’s often used in fencing applications.

- Barbed wire: This type features sharp barbs along the wire, making it suitable for security purposes.

Construction Applications

- Reinforcement: Steel mesh is a crucial component in concrete construction, providing reinforcement and preventing cracking.

- Fencing: It’s used to create fences, gates, and enclosures for various purposes, including security, animal containment, and property delineation.

- Mesh flooring: Expanded metal mesh is used in industrial flooring applications, offering durability, slip resistance, and open-grid design for drainage and ventilation.

- Safety nets: Steel mesh nets are used in construction and industrial settings to prevent falls and injuries.

- Scaffolding: It’s incorporated into scaffolding systems to provide stability and support.

Industrial Applications

- Filtering and screening: Steel mesh is used in filtration systems to separate solids from liquids or gases, and in screening applications to size particles.

- Sieving: It’s employed in sieving processes to separate materials based on particle size.

- Reinforcement: In industrial equipment, steel mesh provides reinforcement for structures and components.

- Machinery components: It’s used in various machinery components, such as conveyor belts, sieves, and filters.

- Industrial filtration systems: Steel mesh filters are used in a wide range of industries, including food processing, chemical manufacturing, and environmental remediation.

Agricultural Applications

- Animal enclosures: Steel mesh is used to construct sturdy and durable enclosures for livestock and poultry.

- Soil erosion control: It’s employed in soil erosion control measures, such as gabions and wire baskets, to stabilize slopes and prevent erosion.

- Agricultural machinery: Steel mesh is used in various agricultural machinery components, providing strength and durability.

- Greenhouse structures: It’s used in the construction of greenhouses, offering support and ventilation.

- Agricultural fencing: Steel mesh fences are used to contain livestock and protect crops.

Decorative Applications

- Sculptures and art installations: Artists utilize steel mesh to create unique and visually appealing sculptures and installations.

- Wall coverings: Expanded metal mesh can be used as a decorative wall covering, adding a modern and industrial aesthetic to interior spaces.

- Architectural elements: Steel mesh can be incorporated into architectural elements, such as facades, railings, and staircases, to enhance visual interest and functionality.

- Interior design: It’s used in interior design elements, such as light fixtures, furniture, and partitions.

- Outdoor decor: Steel mesh can be used to create decorative elements for outdoor spaces, such as planters, trellises, and screens.

Factors to Consider When Choosing Steel Mesh

- Size: The size of the mesh openings determines its filtration or screening capabilities.

- Strength: The thickness and type of wire used affect the mesh’s strength and durability.

- Corrosion resistance: For outdoor applications, the mesh should be made of a material that is resistant to corrosion.

- Cost: The cost of steel mesh varies depending on the type, size, and material.

- Specific application: The intended use of the mesh will influence the choice of material, size, and pattern.

By understanding the diverse applications and key considerations, you can select the appropriate steel mesh for your specific needs and projects.

price table

| Product Description | Mesh Size (mm) | Wire Diameter (mm) | Width (m) | Length (m) | Price (USD/ton) |

|---|---|---|---|---|---|

| Welded Steel Mesh | 50×50 | 2.0 | 1.0 | 2.0 | $700 |

| Welded Steel Mesh | 75×75 | 2.5 | 1.2 | 2.4 | $715 |

| Galvanized Steel Mesh | 50×50 | 2.5 | 1.5 | 3.0 | $730 |

| Galvanized Steel Mesh | 100×100 | 3.0 | 2.0 | 4.0 | $745 |

| Stainless Steel Mesh | 50×50 | 2.0 | 1.0 | 2.0 | $760 |

| Stainless Steel Mesh | 75×75 | 2.5 | 1.2 | 3.0 | $775 |

| Welded Galvanized Mesh | 100×100 | 3.0 | 1.5 | 4.0 | $790 |

| Expanded Steel Mesh | 50×50 | 2.0 | 1.0 | 2.0 | $800 |

The table above presents a range of steel mesh prices, featuring different types of steel mesh products, including welded steel mesh, galvanized steel mesh, stainless steel mesh, and expanded steel mesh. Prices range between $700 and $800 per ton, depending on the specifications such as mesh size, wire diameter, and dimensions.

For example, a welded steel mesh with a 50×50 mm mesh size and a 2.0 mm wire diameter, measuring 1.0×2.0 meters, is priced at $700 per ton. Similarly, оцинкованный steel mesh with a larger 100×100 mm mesh size and 3.0 mm wire diameter is available for $745 per ton. Stainless steel mesh, which provides additional corrosion resistance, is priced slightly higher, ranging from $760 to $775 per ton based on the mesh size and dimensions. The highest price in the table is for expanded steel mesh, which costs $800 per ton.