pipe laser cutting price calculation

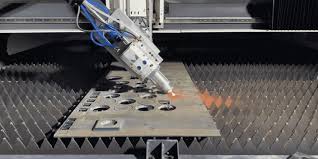

Pipe laser cutting is a precision manufacturing process that uses a focused laser beam to cut through various materials, including pipes. The price of pipe laser cutting can vary significantly based on several factors. Here’s a breakdown of the key elements that influence the cost:

Factors Affecting Pipe Laser Cutting Price

- Material: The type and thickness of the material play a crucial role. For example, stainless steel is generally more expensive to cut than mild steel.

- Pipe Diameter and Wall Thickness: Larger pipes and thicker walls require more processing time and energy, leading to higher costs.

- Cutting Complexity: Intricate patterns or precise tolerances can increase the cutting time and complexity, affecting the price.

- Quantity: Larger quantities often result in economies of scale, leading to lower unit costs.

- Laser Power: The power of the laser machine determines its cutting speed and capacity. Higher-powered lasers can cut thicker materials more efficiently but are generally more expensive to operate.

- Machine Efficiency: The efficiency of the laser cutting machine itself can impact the overall cost. Newer, more advanced machines may be more efficient, leading to lower operating costs.

- Labor Costs: The cost of labor involved in preparing the pipes, operating the machine, and handling the finished products can vary depending on the location and the company’s labor rates.

- Overhead Costs: Overhead expenses, such as rent, utilities, and insurance, also contribute to the overall cost.

Obtaining a Precise Quote

To get an accurate price estimate for your pipe laser cutting project, it’s best to consult with a reputable laser cutting service provider. They can assess your specific requirements, provide a detailed quote, and offer valuable advice on optimizing your design for efficient cutting.

When requesting a quote, be sure to provide the following information:

- Material type and grade

- Pipe dimensions (diameter and wall thickness)

- Desired cutting pattern or design

- Quantity required

- Any special tolerances or surface finishes

By understanding these factors and providing the necessary information, you can obtain a more accurate and relevant price quote for your pipe laser cutting project.

Pipe Laser Cutting Quality: A Comprehensive Guide

Pipe laser cutting has revolutionized the manufacturing industry, offering precision, efficiency, and high-quality results. The quality of the cut depends on several factors, including the laser type, machine setup, material properties, and operator skill.

Key Factors Affecting Pipe Laser Cutting Quality

-

Laser Type:

- Fiber lasers: Often preferred for their high power density and efficiency, especially for cutting thicker materials.

- CO2 lasers: Suitable for a wider range of materials, including plastics and non-metals.

-

Machine Setup:

- Focus: Proper focus adjustment is crucial for achieving clean cuts.

- Cutting speed: The speed must be optimized based on the material thickness and laser power.

- Assist gas: The choice of assist gas (e.g., oxygen, nitrogen) can significantly impact cut quality.

-

Material Properties:

- Thickness: Thicker materials may require higher laser power and slower cutting speeds.

- Composition: The chemical composition of the material can influence cutting parameters and results.

- Surface finish: The initial surface condition can affect the cutting process.

-

Operator Skill:

- Experience: Skilled operators can optimize machine settings and identify potential issues.

- Training: Proper training ensures that operators understand the nuances of pipe laser cutting.

Quality Metrics

- Edge Quality: The cut edge should be smooth, free from burrs, and consistent in width.

- Dimensional Accuracy: The cut parts should adhere to the specified dimensions with minimal deviation.

- Surface Finish: The surface of the cut should be smooth and free from defects.

- Taper: The angle of the cut face should be consistent and within tolerance.

- Kerf Width: The width of the cut should be as narrow as possible while maintaining quality.

Ensuring High-Quality Results

- Regular Maintenance: Preventive maintenance of the laser cutting machine is essential for optimal performance.

- Quality Control: Implement a quality control system to monitor and measure cut quality.

- Material Testing: Conduct material tests to determine the best cutting parameters.

- Operator Training: Provide ongoing training to keep operators updated on industry best practices.

By carefully considering these factors and implementing appropriate measures, manufacturers can achieve consistently high-quality results from pipe laser cutting.

pipe laser cutting prices

| Material Type | Cutting Thickness (mm) | Average Price (USD/ton) |

|---|---|---|

| Carbon Steel | 1-3 mm | 300 |

| Carbon Steel | 3-6 mm | 350 |

| Carbon Steel | 6-10 mm | 400 |

| Stainless Steel | 1-3 mm | 350 |

| Stainless Steel | 3-6 mm | 400 |

| Stainless Steel | 6-10 mm | 450 |

| Aluminum | 1-3 mm | 350 |

| Aluminum | 3-6 mm | 400 |

| Aluminum | 6-10 mm | 450 |

| Copper | 1-3 mm | 400 |

| Copper | 3-6 mm | 450 |