-

Desk of Contents

- Analyzing the Purposes of P355GH and P355NH within the Industrial Sector

- Understanding the Weldability of P355GH and P355NH

- Analyzing the Corrosion Resistance of P355GH and P355NH

- Evaluating the Mechanical Properties of P355GH and P355NH

- Exploring the Chemical Composition Variations Between P355GH and P355NH

- Conclusion

“P355GH: Energy and Sturdiness, P355NH: Enhanced Efficiency and Reliability!”

Analyzing the Purposes of P355GH and P355NH within the Industrial Sector

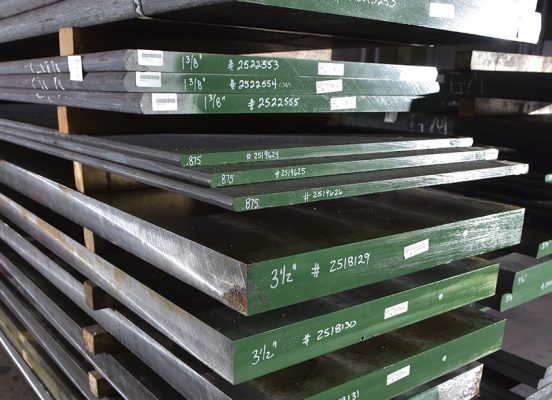

The commercial sector is a serious client of metal merchandise, and two of essentially the most generally used metal grades are P355GH and P355NH. Each of those steels are a part of the EN 10028-2 customary, and they’re utilized in a wide range of functions. On this article, we are going to analyze the functions of P355GH and P355NH within the industrial sector.

P355GH is a strain vessel metal grade that’s utilized in a variety of functions. It’s a normalized metal grade with glorious weldability and notch toughness. It’s used within the fabrication of strain vessels, boilers, and warmth exchangers. It is usually used within the development of storage tanks and different parts that require excessive energy and corrosion resistance.

P355NH is a normalized metal grade that’s utilized in a wide range of functions. It’s a low alloy metal grade with glorious weldability and notch toughness. It’s used within the fabrication of strain vessels, boilers, and warmth exchangers. It is usually used within the development of storage tanks and different parts that require excessive energy and corrosion resistance.

Each P355GH and P355NH are used within the industrial sector for a wide range of functions. They’re used within the fabrication of strain vessels, boilers, and warmth exchangers. They’re additionally used within the development of storage tanks and different parts that require excessive energy and corrosion resistance. Each of those steels are extremely immune to corrosion and have glorious weldability and notch toughness.

In conclusion, P355GH and P355NH are two of essentially the most generally used metal grades within the industrial sector. They’re used within the fabrication of strain vessels, boilers, and warmth exchangers. They’re additionally used within the development of storage tanks and different parts that require excessive energy and corrosion resistance. Each of those steels are extremely immune to corrosion and have glorious weldability and notch toughness.

Understanding the Weldability of P355GH and P355NH

The weldability of P355GH and P355NH is a vital consideration for any engineer or fabricator working with these supplies. Each supplies are carbon-manganese steels with comparable chemical compositions, however they differ of their mechanical properties. This text will analyze the weldability of P355GH and P355NH with a purpose to present a greater understanding of their respective properties.

P355GH is a strain vessel metal grade with good weldability and excessive resistance to brittle cracking. It’s utilized in a wide range of fabrication processes similar to welding, forming, and machining. The fabric has glorious chilly forming properties and is simple to weld utilizing typical strategies. It is usually immune to intergranular corrosion and has good notch toughness.

P355NH is a normalized metal grade with good weldability and excessive resistance to brittle cracking. It’s utilized in a wide range of fabrication processes similar to welding, forming, and machining. The fabric has glorious chilly forming properties and is simple to weld utilizing typical strategies. It is usually immune to intergranular corrosion and has good notch toughness.

When welding P355GH to P355NH, you will need to think about the preheat temperature and post-weld warmth therapy. Preheat temperatures ought to be between 150-200°C for P355GH and 200-250°C for P355NH. Submit-weld warmth therapy ought to be carried out at temperatures between 500-650°C for each supplies.

In conclusion, P355GH and P355NH are each carbon-manganese steels with comparable chemical compositions and good weldability. Nevertheless, they differ of their mechanical properties and require completely different preheat temperatures and post-weld warmth therapies. It is very important think about these elements when welding these supplies with a purpose to guarantee the very best outcomes.

Analyzing the Corrosion Resistance of P355GH and P355NH

Evaluating the Mechanical Properties of P355GH and P355NH

The mechanical properties of P355GH and P355NH are necessary issues when choosing a cloth for a selected utility. Each supplies are strain vessel steels, and they’re comparable in lots of respects. Nevertheless, there are some key variations of their mechanical properties that ought to be taken under consideration when making a range.

P355GH is a normalized metal grade with a minimal yield energy of 355 MPa and a minimal tensile energy of 490-630 MPa. It’s a strain vessel metal grade utilized in all kinds of functions, together with boilers and strain vessels. It has good weldability and is simple to kind and machine.

P355NH is a non-alloy metal grade with a minimal yield energy of 355 MPa and a minimal tensile energy of 490-630 MPa. It is usually a strain vessel metal grade, but it surely has larger mechanical properties than P355GH. It has glorious weldability and is simple to kind and machine.

When evaluating the mechanical properties of P355GH and P355NH, you will need to observe that P355NH has larger yield and tensile energy than P355GH. This makes it extra appropriate for functions that require larger energy and toughness. Moreover, P355NH has higher weldability and formability than P355GH.

In conclusion, P355GH and P355NH are each strain vessel steels with comparable properties. Nevertheless, P355NH has larger mechanical properties than P355GH, making it extra appropriate for functions that require larger energy and toughness. Moreover, P355NH has higher weldability and formability than P355GH.

Exploring the Chemical Composition Variations Between P355GH and P355NH

Conclusion

In conclusion, the principle distinction between P355GH to P355NH is that P355GH is a strain vessel metal grade with good weldability and excessive resistance to brittle cracking, whereas P355NH is a normalised metal grade with a minimal yield energy of 355 N/mm2 and with good weldability. Each metal grades are used within the oil and fuel, petrochemical and chemical industries.